BlueScope is committed to innovation and continuous improvement of product performance. Clean COLORBOND® M steel applied new generation ZINCALUME® M steel as substrate, extending the product life. In the meanwhile, the paint system was developed for more excellent long-term appearance.

Introduction

Clean COLORBOND® M steel has been at the forefront of prepainted steel technology and product innovation in Asia for many years. It combines the superior of steel, the corrosion resistance and protection of a ZINCALUME® M steel substrate and the long lasting beauty of an oven cured paint system, offering remarkable resistance to chipping, peeling and fading. Clean COLORBOND® M steel was developed by BlueScope Steel to resist staining and discolouration, to give your building long lasting beauty.

-

01

Superb color fading and chalking resistance

-

02

Reliable paint peeling resistance

-

03

Unique Clean fuction

-

04

Excellent Corrosion Resistance

Superb color fading and chalking resistance

The high-quality paint system of Clean COLORBOND® M steel provides superb color fading and chalking resistance, which keeps the building with long-lasting beauty.

Two main painting systems of Clean COLORBOND® M steel: Special Reinforced Polyester (SRP) and Polyvinylidene Fluoride (PVDF)

Special Reinforced Polyester (SRP) system: evaluated and proven by BlueScope Australia R&D Center, the paint system has high durability due to its outstanding decomposing resistance, which was tested under long-term sunlight exposure with high temperature in a real-life environment. Product: Clean COLORBOND® M XRW steel.

Polyvinylidene Fluoride (PVDF) system: formulated with PVDF resin of international brands (such as Kynar® 500 and Hylar® 5000), the paint system performs much better than commercialized PVDF paint.Product: Clean COLORBOND® M XPD steel.

During the development of science and technology, BlueScope combined a variety of new developed materials with the special reinforced polyester (SRP) for new painting system. After a series of comprehensive and strict laboratory testing, accelerated testing and more than 6 years of field evaluation, BlueScope finally filtered out the painting system with the most excellent performance. The painting system greatly improves the color fading and chalking resistance of Clean COLORBOND® M steel, which enhances the long-lasting beauty for buildings.

In addition, the paint system of Clean COLORBOND® M steel formulated with inorganic ceramic pigments. Inorganic ceramic pigment has long-term stable durability, particularly in the aspects of ultraviolet resistance and decomposing resistance, comparing to organic pigments.

Reliable paint peeling resistance

The two paint systems of Clean COLORBOND® M steel use two types of primers accordingly:

-

High UV-resistant polyester primers for special reinforced polyester (SRP) paint system

High durable polyurethane primer for Polyvinylidene Fluoride (PVDF) paint system

The two paint systems ensure the reliable paint adhesion of Clean COLORBOND® M steel, avoid paint peeling and makes it stable for the long-term building appearance.

Paint peeling is the phenomenon of paint aging after long-term outdoor use, which the paint appears cracking and flaking. The main factors that cause paint peeling are: long-term UV exposure, low-quality pretreatment, poor paint formulation or inappropriate topcoat and primer combination.

BlueScope polyester primer of Clean COLORBOND® M XRW steel offers better UV resistance than the epoxy primer commonly used in the market, which ensures no paint peeling for the long period of use.

In addition, the new painting system enhances the durability of the topcoat. In longer period of product service life, it can effectively prevent UV from damaging the primer through topcoat, making the paint peeling resistance even longer.

Unique Clean fuction

The unique clean function of Clean COLORBOND® M steel provide the product with effective dirt-stain resistance. The revolutionary paint system prevents the dirt particles adherence onto the surface of the prepainted steel.

The stain on a building is often caused by the adherence of dirt particles. During the changing of temperature and humidity, dirt particles tightly bond onto the surface of prepainted steel. The accumulation of more and more dirt particles causes the building dirty and aged.

Dirt particle, in a loose state (Figure A) when left on the surface of the prepainted steel, is easily washed away by rain, which prevents the dirt particle bonding onto the surface and therefore, avoid dirt stain. In contrast, dirt particles firmly bond onto the conventional prepainted steel surfaces (Figure B), creating dark dirt stain that are difficult to remove.

Excellent Corrosion Resistance

ACTIVATE Technology from Australia

In early 1990s, BlueScope started developing “Aluminum-Zinc-Magnesium” metal alloy coating, also known as ACTIVATE technology. Through large number of tests, the results have shown significant performance improvement in Aluminum-Zinc steel by adding 2% of Magnesium.

ACTIVATE technology includes two main aspects: alloying coating and manufacturing process. After proving the corrosion resistance of the alloy coating in lab, BlueScope continues to experiment and improve manufacturing process to ensure correct dispersion of Magnesium in the coating, thus optimizes the best product quality and long-term performance.

Clean COLORBOND® M steel uses BlueScope new generation leading edge technology ZINCALUME® M steel as substrate, coating mass AZM150. Corrosion resistance of steel surface and cutting edge are greatly improved comparing to 55% Aluminum-Zinc coated steel, which leads to an extend of the product service life. With its long-lasting beauty, the product now has a super longer service life. Whatever in industrial environment or in marine environment, Clean COLORBOND® M steel performs outstanding.

Innovative Energy Efficiency

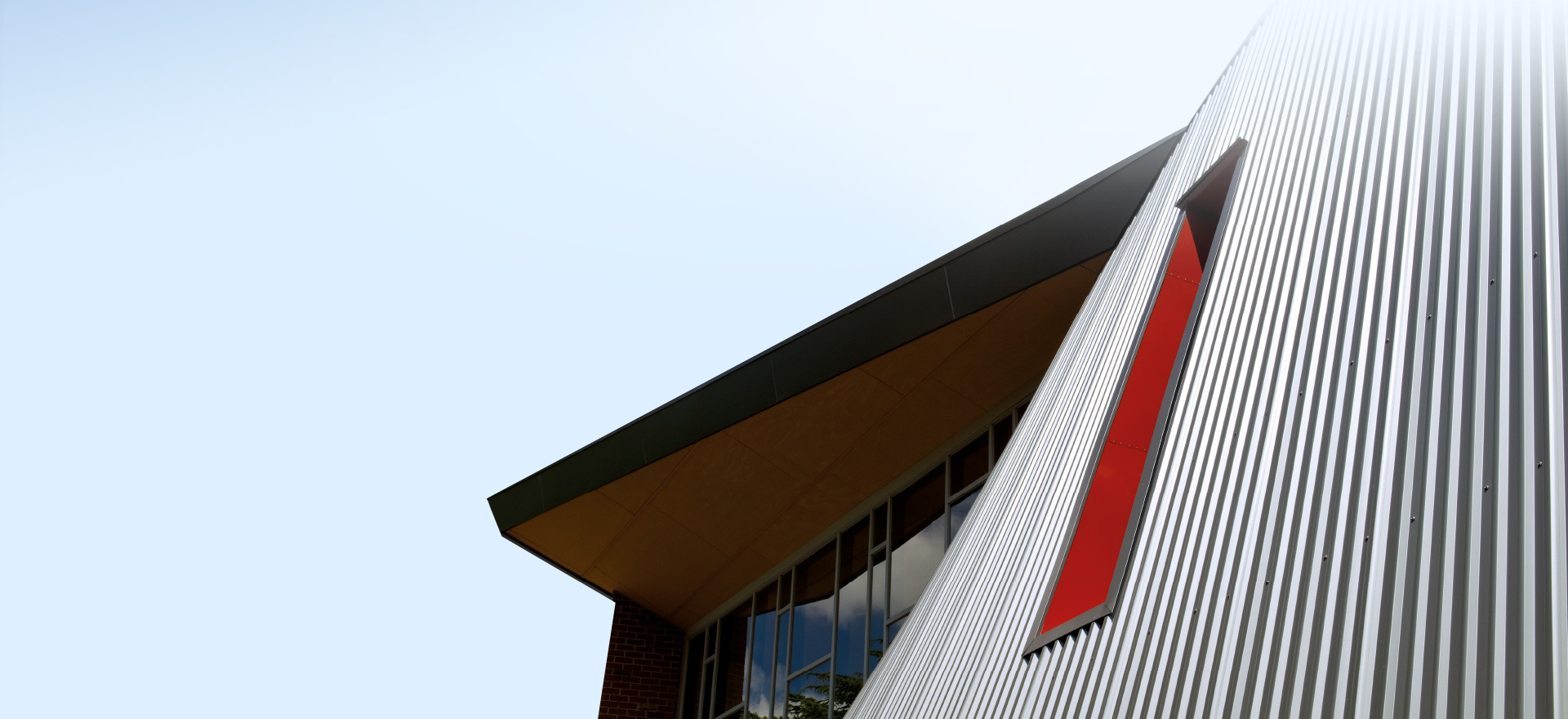

Realization of Unlimited Creativity

-

Shinning and Sparkling

BlueScope strives for product innovation, not only in performance improvement but also bring new technology to the product aesthetics. BlueScope offers 3 series of products to meet various needs of metallic colors.

-

-

Clean COLORBOND® M XTM steel

Versatile sparkling in layers

-

Clean COLORBOND® M steel – SPECTRUM SERIES

Mica pearl for shinning

-

Clean COLORBOND® M PEARLESCENT steel

Prestige shinning for art

-

Good Processing Property

Clean COLORBOND® M steel is available for both wide span building design and complex curve profiles.

Mid-grade G300/G350

Ideal for roll forming in different cladding profiles such as screw down sheets, standing seaming sheets, corrugated profile, etc. The flexibility also fit for curved shape and creative building envelope.

High-grade G550

Good for reducing raw material volume usage due to high yield strength. It is a good fit for wide span structure system.

Reliable Quality and Long-term Performance Warranty

BlueScope conduct strict and entire product quality tests after every coil production. The test results are recorded in “Test Certificate”, which is delivered to the customer after the coil dispatch.

BlueScope offer long-term product warranty for Clean COLORBOND® M steel according to customer application and on-site environment.

A maximum 30 years warranty is offered when using Clean COLORBOND® M steel with ACTIVATE technology, which includes 20 years paint system warranty.

* Please contact BlueScope sales office for information on product warranty.

Six Series Prodcuts Meet Different Needs

Prodcut Name